Newsletter - June 2023

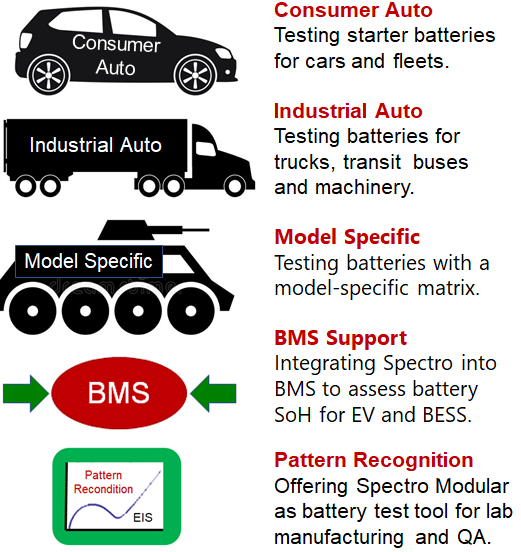

| A product must serve multiple markets to get a strong return on investment. The Spectro Modular (Brick) fits this model as illustrated in Figure 1. We go beyond Consumer Auto and including Industrial Auto with large starter batteries. We also develop model-specific matrices for specialty batteries and Research finds ways to integrate Spectro™ into BMS to monitor the state-of-health (SoH) of EVs and BESS. The Brick also captures Nyquist plots by reading the electrochemical evidence with a frequency scan as part of Pattern Recognition. We are currently working with the US Army to learn why AGM batteries in some armored vehicles only last 13 months. In 2016, the US Army spent over $80 million to replace 373,000 batteries; under–usage may be the cause. The saying goes: “Use it or lose it.” These batteries should be able to restore by removing the sulfation. A six-month topping charge in dormancy is recommended. |

Figure 1: Building a tool that tests most batteries.

|

Figure 2: Spectro CA-12

|

Figure 3: Spectro Modular (Brick)

|

EIS Simplification

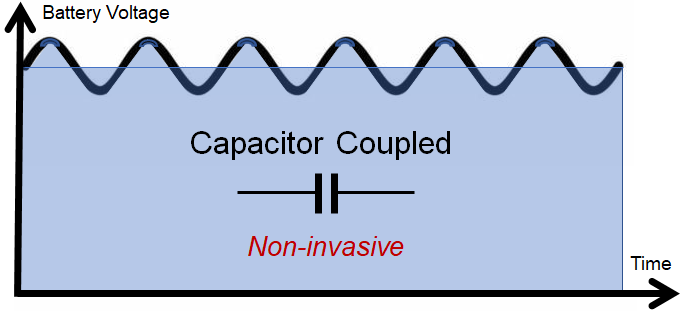

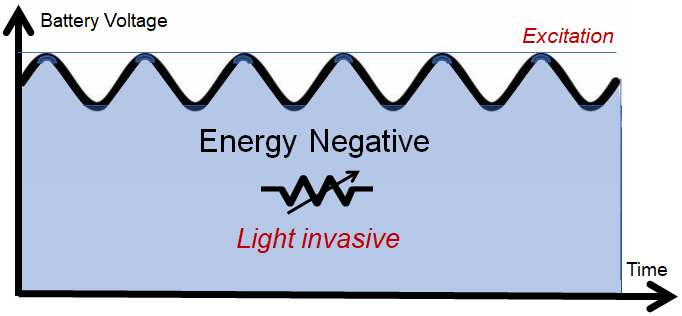

The Brick is a redesign of the CA-12 introduced in 2004 of with we sold 8,500 units to date. While the CA-12 is capacitor-coupled, the Brick uses Energy Negative by superimposing a sinewave to produce the needed voltage ripple. Eliminating capacitors permits testing large batteries of up to 300Ah with ultra-low frequencies going down to 0.1 Hertz. Figure 4 illustrates the two methods. The Brick also enables cloud connectivity

Capacitor Coupled Scan is non-invasive but requires large capacitors testing bigger batteries

|

Energy Negative Scan is light invasive but enables testing large batteries with small footprint

|

Consumer Auto

Consumer Auto is mostly served by battery testers that verify power by applying a load to check the voltage drop and calculate the internal resistance. Without also assessing the capacity that Spectro™ provides, we ask: “So your engine cranks, but will the battery start the car next week?”

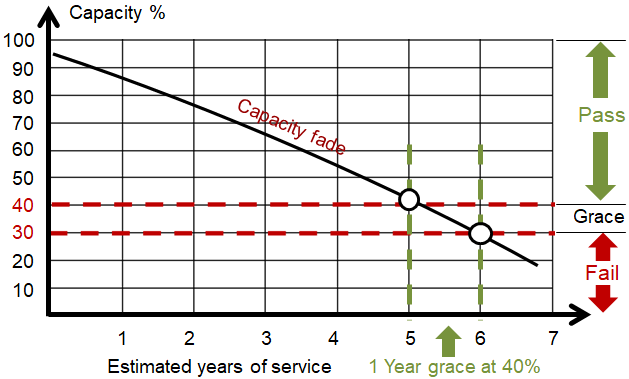

Spectro™ provides the Remaining Useful Life (RUL) of a battery. We do this by setting the pass/fail threshold to 40% while the capacity can go down to 30% and still crank the engine. A pass at 40% gives typically a one year grace, good to the next service. Please note that cranking can be strong with very low capacity before the battery suddenly fails without warning. The Pass/fail for portable batteries is typically set to 80%, controlled by the Target Selector. Here, runtime relates purely to capacity.

Industrial Auto

Best results with Spectro are achieved by testing a battery in a tranquil but active state with sufficient state-of-charge (SoC) and at room temperature. Agitated batteries should be rested for an hour or so; dormant packs taken from long storage may require activation with BattPrep. An analogy is a patient preparing for a medical exam.

Model Specific

Spectro is most effective with a model-specific matrix that we will develop with user assistance. These batteries are commonly deployed in transit buses and armored vehicles with hotel load needs. A further market is batteries in heavy machinery. The pass/fail threshold for these batteries should be set higher than 40% common for starter batteries to assure sufficient capacity.

BMS Support

Batteries in EVs and BESS are served by a BMS. While a BMS is effective in detecting anomalies and tracking charge and load activities, capacity estimation is ineffective unless assisted by coulomb counting. EIS assesses battery capacity by taking the electrochemical evidence with a frequency scan, modeling and using AI to assess state-of-health, a technology that resembles face recognition.

Pattern Recognition

Pattern Recognition provides quality control by creating a Nyquist plot of a battery by a frequency scan. The Brick offers this service at a fraction of cost to competitive devices. The user can create a “golden sample” by scanning a known good battery and do comparisons and overlay. Pattern Recognition assists labs, academia and battery manufacturing.

Conclusion

Multi-model EIS presents a new level of battery testing. The conclusive advantage is getting some assurance of remaining useful battery. This is made possible by capacity measurement and setting of Minimal Operational Reserve Energy (MORE) with familiarity of capacity decline. We include these features in our battery test devices to usher in Deep Battery Diagnostics (DBD), a technology that will change the way batteries are tested.