Feb 2024 - Article

Electrification calls for advancements in battery diagnostics to track Minimum Operational Reserve Energy (MORE). MORE is a performance standard that maintains system reliability as batteries fade without the user noticing. Progress in battery diagnostics is visible in portable applications and electric vehicles deploying modern Battery Management Systems (BMS) with Li-ion batteries.

|

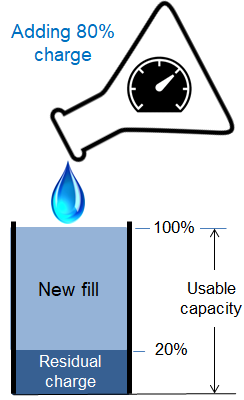

Deficiency in battery diagnostics remains mainly with lead acid systems that do not allow coulomb counting to track in-and-out-flowing currents. Examples are starter batteries in vehicles and stationary batteries sitting on standby mode. One coulomb is 1A per second on either charge or discharge. This value is utilized to estimate the battery's state of charge and state of health by assessing the available energy storage. An example is reading the residual charge of a battery by voltage and then measuring the coulombs added to full charge. Residual plus new fill equals available capacity. Improved diagnostics are required for starter batteries in vehicles and machinery. This includes hybrid batteries in buses and armored vehicles that draw hotel loads. A third battery pool is standby applications that are only occasionally used. These batteries are commonly tested by voltage and internal resistance to secure power delivery. What’s missing is capacity that fades unnoticed while power remains strong and voltage readings stay normal. Capacity testing by a discharge/charge is not practical for large batteries and causes unnecessary wear. |

Real (Z) (mΩ) |

A DOE official said: “Every year roughly one million usable lithium-ion batteries are sent for recycling.” The end of battery life may be by date stamp without a capacity check. Under-usage is also common, especially in healthcare and defense where batteries are stored for readiness.

Defense, including the US Army, discards tons of batteries, in part due to inactivity. Roughly 75% of vehicles on standby are driven less than 3,000 miles per year, causing battery sulfation. Sulfation is a film buildup that develops when a lead acid battery is being deprived of a full charge for six months or more. This state decreases performance, a condition that can be reversed if serviced in time.

|

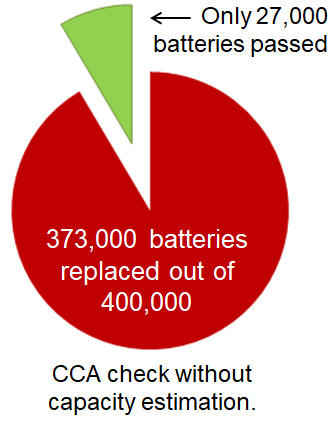

Records show that batteries in armored vehicles were replaced every 13 months on average, breaking the expected life expectancy of six to eight years. In the fiscal 2016 alone, the U.S. Department of Defense replaced more than 373,000 batteries in a pool of 400,000 at a cost of over $80 million. (A published report is in https://asc.army.mil/web/news-alt-ond17-harnessing-the-sun/.) Technology is available that assesses the condition of a battery and applies corrective service to put packs back on the road. Source: U.S. Army photo by Chip Herrell, |

Figure 2: Battery disposal yard at Kandahar Airfield |

Aging Effect of Batteries

Armored vehicle batteries are hybrid to provide power for cranking, as well as capacity for hotel load when the engine is turned off. Cranking ability is measured in Cold Cranking Amps (CCA) while capacity refers to residual energy delivered over time in Ah.

CCA and capacity do not degrade equally. Capacity tends to drop gradually while CCA can stay high to the end. Cadex labs reveal a capacity to CCA correlation of only 55%. This means that CCA is an insufficient performance indicator. Tests reveal that capacity-fade causes 48% of all battery failures; CCA is only 12%. Other failures are low voltage that could be caused by low charge or a shorted cell.

|

The high battery failure rate of DoD may have been due to inadequate test methods. Most devices correlate CCA to internal resistance, a reading that gets distorted when the resistance rises by sulfation. We now scan batteries with the Explorer in an entire pack, as well as in parallel pairs. Figure 6 shows an open e-bike battery; Figures 7, 8, and 9 show the test results. There are two types of sulfation: reversible (soft) and permanent (hard). In armored vehicles that are only used occasionally, sulfation is likely reversible when driving in a vehicle. A more effective is an overcharge that raises the voltage above the set level for a time. Spectro™ devices by Cadex estimate battery state-of-health by capacity and CCA. For automotive use, the pass/fail capacity threshold is set at 40% and 50% for CCA. These settings appear low but work well in consumer auto that uses minimal hotel load. Lab tests reveal that a battery still cranks with a capacity below 30%. |

|

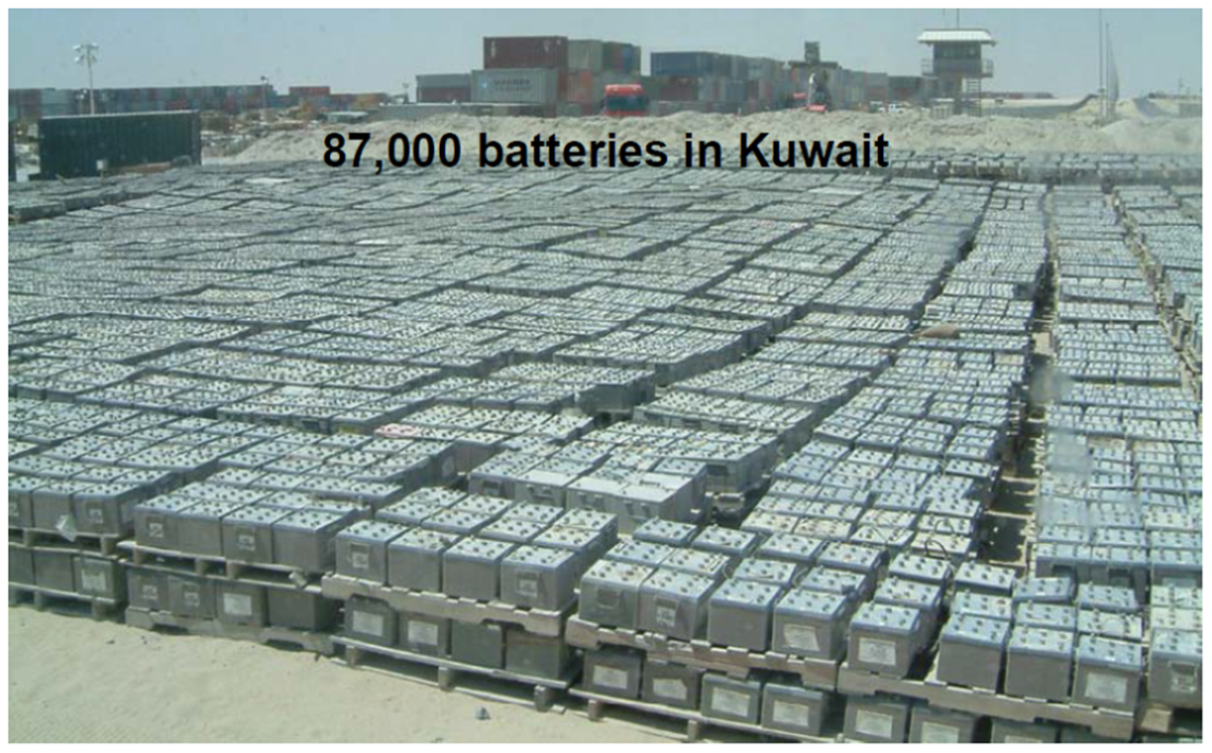

With the absence of capacity measurement, vehicle batteries may only get CCA tested. To satisfy defense application, CCA pass/fail threshold may be set unreasonably high, a level that will not relate to battery performance but incorrectly fail good packs. For all we know, the army may have replaced 373,000 batteries for lack of adequate test technology. Large tonnages of batteries were also replaced after the war in Kuwait. Advancement in battery diagnostics with MORE will reduce this wastage.

Unusable vehicle batteries in Kuwait