C8000 Battery Testing System

By all imagination, the Cadex C8000 may well be the most complete and affordable battery testing system available today.

The Cadex C8000 stands in a class by itself in flexibility and affordable price. Test SMBus batteries, monitor cell balance and capture load signatures to observe batteries with a unique load protocol. Add a thermal chamber, an external load bank, a safety circuit and alarm to form a command center and you begin realizing the unique qualities of this fine battery testing system.

- 4 independent digital drivers for maximum flexibility

- 1.2V – 36V, 10A charge and discharge per channel

- 100W per channel on charge; 80W on single channel discharge, 160W dual channel, and 2400W with external load bank

Features

|

Digital technology widens the test range, provides ultimate stability and gets more power into a compact housing than is possible with analog devices. Each channel can be programmed with up to 10A charge and discharge current each. Power handling is 100W per channel on charge and 80W on discharge, or 400W on charge and 320W on discharge on all four channels. The Cadex C8000 is more than a programmable power supply and load bank; the instrument has intelligence to assist in safe battery testing. Protected charge and discharge algorithms with redundant safety features identify a faulty battery and safely terminate the service should an anomaly occur. The system can be overridden for destructive tests. |

Separate Battery and I/O Ports

LABORATORY SYSTEM

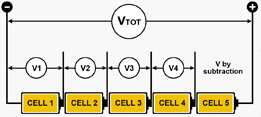

Monitoring individual cells

| Four differential (floating) analog inputs enable voltage check of up to 5 cells; 4 direct and one by voltage extraction. |

|

Load Capture

external load bank

Dual Power Port Cable

| The Dual Power Port Cable ties two channels together to double the current from 10A to up to 20A. Applicable on discharge only. |

|

Smart Battery testing

Load TEST

LIFECYCLE TEST

Service Programs

The automated programs are grouped into Basic, Advanced, Rapid-test and Custom programs.

basic Programs

| Charge | Applies fast charge; trickle when applicable. |

| Auto | Exercises batteries with charge-discharge-charge. Applies recondition on nickel-based batteries to reverse memory if user-set target capacity cannot be reached. |

| Prime | Prepares batteries with discharge-charge-discharge by repeated cycling until maximum capacity is reached. The first reading is the spare capacity before charge. |

| Extended Prime | 16-hour trickle charge prior to Prime. Prepares difficult to charge batteries |

| Boost | Activates batteries that became deactivated due to low discharge. |

Advanced Programs

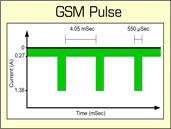

| Load Test | Tests batteries under simulated GSM, CDMA and other discharge protocols, 50μs steps; minimum setting 500μs. |

| Runtime | Allows three different discharge levels; programmable in hours and minutes. |

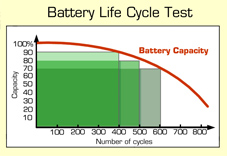

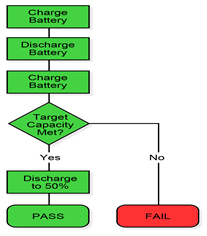

| Lifecycle | Cycles battery until the performance drops the target capacity. |

| Self-Discharge | Measures self-discharge. Identifies stresses leading to compromised safety. |

| Discharge Only | Prepares battery for storage. Also checks charger function. |

| Load Capture | Simulates real life conditions with pre-recorded load. Requires PC-BatteryLab™ and Load Capture Unit to record load signature. |

RAPID TESTS

| OhmTest™ | Measure battery resistance with DC pulses 13 seconds; based on IEC61436. |

| Impedance |

Measures battery resistance with 1000Hz signal. Channel 1 only. Note: Readings of a reactive device differ with DC and AC test methods. |

Custom Programs

|

These programs allow user-defined settings of charge, discharge, recondition, wait and repeat. You can set conditional gates that proceed on a different course if certain criteria are met. Custom works with PC-BatteryLab™ and has a limit of 100 user-defined programs. One of the critical applications of the custom program is preparing a battery for shipping. You may also want to prepare a battery for storage. Note: Supervision recommended in the absence of automated terminations. |

|

Accessories

C8000 Power Port Cables and Auxiliary Cables

RigidArm™ Universal Adapter

Dual Power Port Cables (DPPC)

LOAD CAPTURE UNIT (LCU)

|

Captures load signatures of up to 100A; digitizes the information and replays the recorded load protocol in the Cadex C8000 for simulated battery testing. Part Number: 11-308-0011  |

|

Adapter Unit

The Adapter Unit provides access to SnapLock™ Battery Adapters Accommodates two batteries.

|

|

Software

No test instrument is complete without good software. PC- BatteryLab™ provides a simple yet powerful interface to control and monitor batteries by shifting the operation from the Cadex C8000 to the PC.

BatteryLab™ Software

Specs

|

Standard Components Each Standard System includes |

|

Systems and Ports

| Input Power | 100–240VAC; 50–60Hz; maximum 8A |

| Channels | 4 independent channels, each includes one Battery Port and one I/O Port |

|

Battery Ports 4 ports in front each including: |

|

|

Active Data Ports on back Panel |

|

| Power Port Cable | 4 items, 1.8m (6’) with alligator type clips |

| Auxiliary Cable | 4 items, 1.8m (6’) |

| Dual Port Power Cable | 1 item, 1.8m (6’); connects to channels 1+2 or 3+4; doubles current to 20A |

|

Battery Adapter Unit (2 bays, optional) |

Connects to C8000 to support SnapLock™ battery adapters. List of SnapLock™ Battery Adapters |

Battery and Service

| Battery chemistries |

|

| Battery voltage range |

Nominal 1.2V–36V nominal (max 45V) supports serial connection of:

|

| Maximum Charge Power | 100W per channel; 400W total; power management when exceeding temperature |

| Maximum Discharge Power |

80W per channel; 320W total 160W per channel pair using Dual Power Port cable Note: External Load may be used to increase discharge up to 2400W |

| Maximum Charge/Discharge Current |

30mA to 10A set in 1mA increments 20A maximum discharge rate using Dual Power Port cable External Load may be used to increase discharge up to 240A |

| Output Frequency | Square 2kHz (500 microseconds) |

| Accuracy | Voltage 0.1%; current 0.25% full scale |

| Power Management | Current automatically scaled down with message if power limits are exceeded |

| Charge Methods |

Lead Acid: Constant voltage with current limit, saturation charge, float charge Nickel-based: Constant current; negative slope or plateau timer, trickle charge Li-ion: Constant voltage with current limit, saturation charge, no trickle charge |

| Discharge Methods |

Constant current to set discharge voltage threshold Constant power to set discharge voltage threshold |

| Basic Programs |

Charge: Applies fast charge with termination Auto: Charge-discharge-charge; applies Recondition on nickel-based batteries if user-set target capacity is not met Prime: Discharge-charge-charge. Reads spare capacity, prepares batteries by cycling until maximum capacity is reached. Extended Prime: 16h trickle charge prior to Prime. Prepares difficult batteries. Boost: Activates seemingly dead batteries. |

| Advanced Programs |

Load Test: Tests batteries under simulated GSM, CDMA and other discharge protocols, 50μs steps; minimum setting 500μs. Runtime: Allows three discharge levels, programmable in hours and minutes. Lifecycle: Cycles battery until set target capacity is reached. Self-Discharge: Measures self-discharge. Discharge Only: Prepares battery for shipment and storage. Load Capture: Captures load signature for replay; requires PC-BatteryLab, LCU SMBus: Battery info, fuel gauge calibrate, SMB charge, SMB discharge, FCC |

| Rapid Test Programs |

OhmTest™: Measure battery resistance with DC pulses (IEC61436), 13 seconds Impedance: Measures battery resistance with 1000Hz signal. (Channel 1 only) Note: Readings of a reactive device differ with DC and AC test methods. |

|

Custom Programs (requires BatteryLab) |

Allows 100 user-defined programs of charge, discharge, waits, repeats, etc. Note: Supervision recommended in the absence of automated terminations. |

Data Acquisition

| System Sample Rate | 500 microseconds (once per second) |

| Termination Data Capture Rate | 2–200 microseconds (last 500 samples) |

| Capture/Display Rate | 1–0 seconds (non-termination) |

| Load Capture | Minimum sample rate increment 500 microseconds; number of samples 10–500 |

Certification, Warranty, Physical

| Safety | CSA, UL, CE |

| Environmental | RoHS, WEEE |

| Warranty |

Standard: 2 year limited warranty (materials & workmanship) Extended Warranty (Optional): Additional 2 years (total of 4 years) |

| Calibration | Recommended factory calibration every 1 year; contact Cadex |

| Upgrades | Firmware upgrades enabled by PC-BatteryLab™ software |

|

Dimensions Weight Mounting Option Display |

480mm x 380mm x 140mm (18.9” x 15.0” x 5.5”) 15.5 kg (34 lb) Desktop or 19” (483mm) 3U Rack-mount (brackets included) 5.7” (145mm) QVGA 320x240 graphics with backlight |

External Test Equipment Control

| Environmental Chambers |

Thermotron 2800/3800/8800 Test Equity Watlow 4 |

|

External Digital Loads B&K Precision Programmable DC Electronic Loads 8500 |

8510 (0.1V–120V/120A/600W) 8514 (0.1V–120V/240A/1200W) 8518 (0.1V–60V/240A/1200W) 8520 (0.1V–120V/120A/2400W) |

| Load Capture | Cadex Load Capture Unit (LCU) |

| Security | Password protection |

PC-BatteryLab™

|

System Requirements PC with the following available: |

Windows O/S, Ethernet connection, 1.2 GHz processor, 512 MB RAM 10 GB storage memory |

| License capacity: |

Up to 8 C8000 test systems; Up to 32 individual batteries |

Specifications subject to change